Dual%20Fuel%20Kit%20Or%20RECD%20Kit

KEY BENEFIT POINTS-DUAL FUEL SYSTEM FOR DIESEL GENERATOR

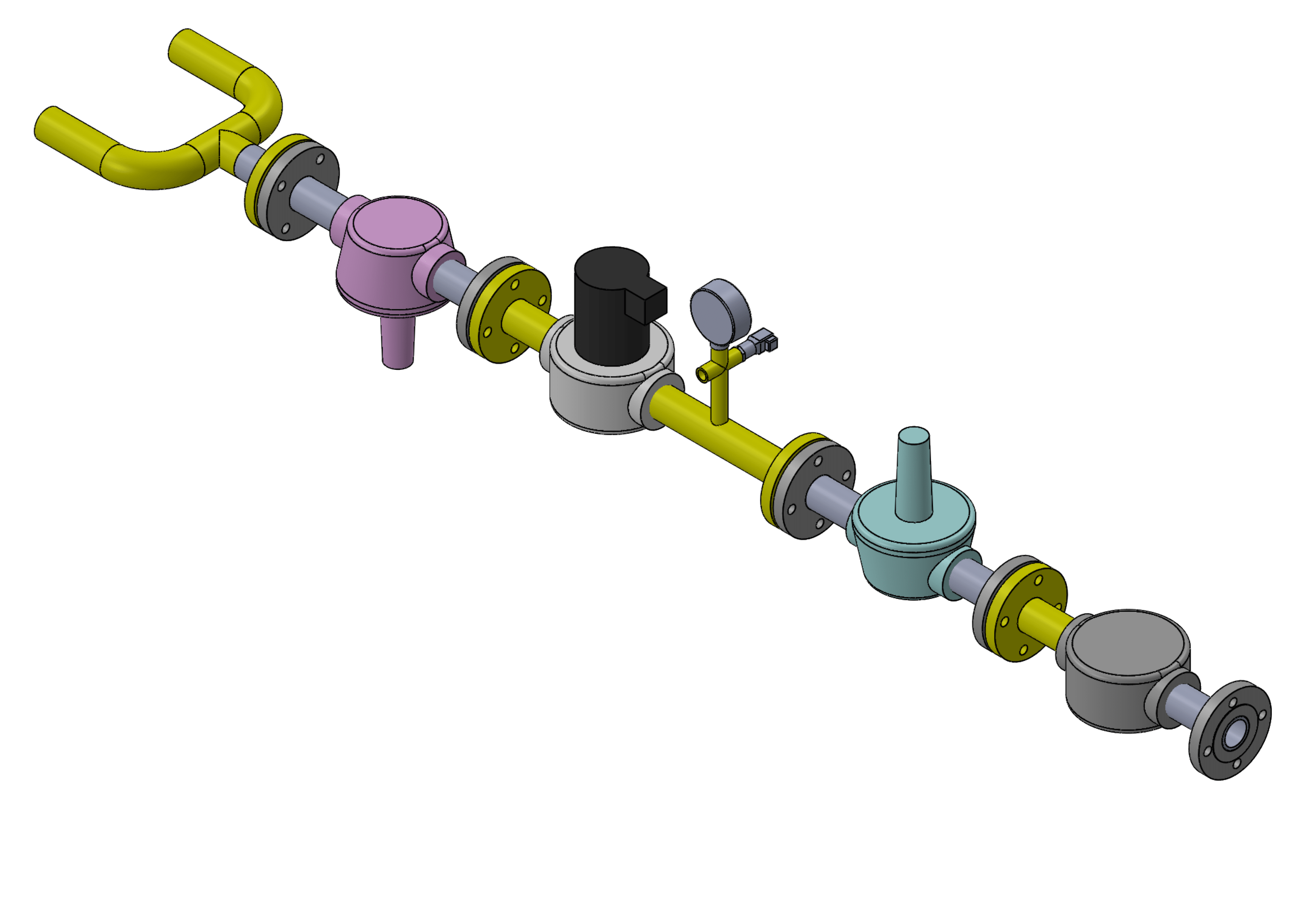

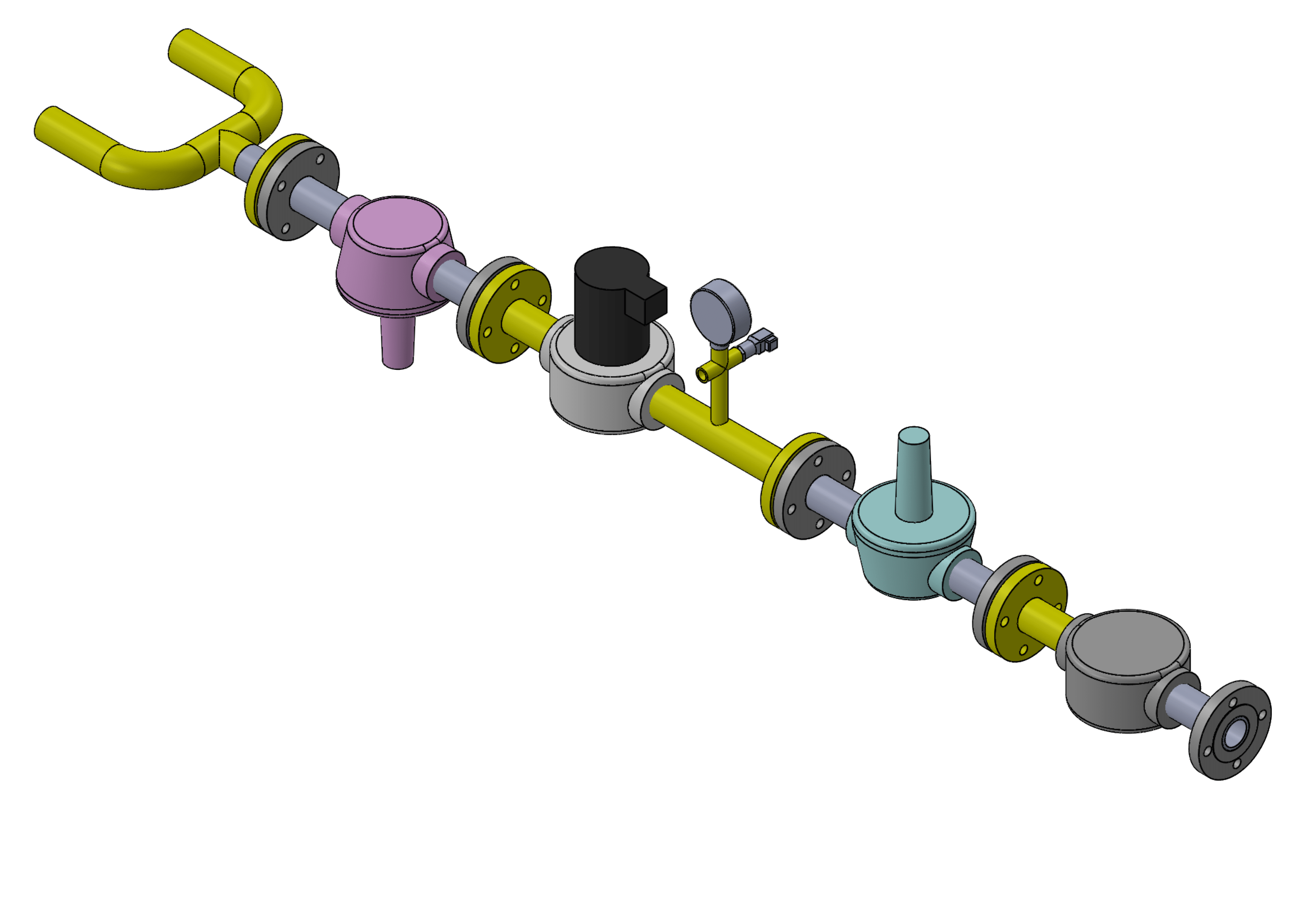

The Dual Fuel System is an innovative technology that enables operators of heavy-duty diesel engines to substantially reduce operational costs and lower emissions by substituting diesel fuel with lower cost, cleaner-burning natural gas. The Dual Fuel System is comprised of patented technologies that allow engines to safely operate on gas percentages up to a maximum of 70%* of the total fuel requirement. Engines converted to Dual Fuel exhibit diesel-like performance in such critical areas as efficiency, stability and load acceptance.

NO ENGINE MODIFICATIONS REQUIRED & NO POWER OR EFFICIENCY LOSSES

A key feature of the Dual Fuel System is its ability to switch fuel modes without interruption in engine power output. The engine can be switched between diesel and gas automatically while maintaining speed and load. This feature gives the user the flexibility to choose between gas and diesel modes as dictated by fuel pricing, fuel availability or other operational considerations. An equally important feature of the Dual Fuel System is its ability to maintain engine power levels while operating in gas mode between the “continuous” and “prime” ratings of the engine. For operations above the programmed power limit, the engine is automatically switched to 100% diesel mode, thus avoiding the necessity to de-rate the engine. In applications where the load varies substantially, our system provides for adjustment of the gas substitution rate according to a map of fuel vs. load. The Dual Fuel System utilizes a state-of-the-art electronic control and monitoring system which monitors critical engine and Dual Fuel System parameters and activates or deactivates gas mode according to programmed limits. When a monitored parameter exceeds the allowable limit, the controller switches the engine to 100% diesel mode and electronically logs the fault for diagnostic purposes.

REDUCED MAINTENANCE & LONGER SERVICE INTERVAL

The Dual Fuel System allows the generator to reduce the carbon contents in comparison to diesel generator. Natural Gas is a clean fuel and using natural gas will diminish carbon emission to less than half with respect to Diesel. Due to above reason, all system of Dual Fuel generator, like lube oils etc. remain clean. Due to this, Dual Fuel System allow to increase the time of maintenance and service for almost just double in contrast to Diesel Generator.

Cost Saving

Displacing a percentage of diesel fuel with methane-based gas provides an immediate economic benefit based on the cost difference between the fuels and the amount of run time of the genset. In high usage gensets, the system can pay for itself in a short period of time. Simple Excel-based spread sheets are available to assist in modeling the economic benefits of converting your diesel genset to Dual Fuel.

INCREASED RUN TIME AND ENHANCED LIFE

Reducing the amount of diesel fuel used extends the run time in proportion to the substitution rate. This provides extra hours of operation for critical applications during extended power outages. Due to use of cleaner fuel mixed with diesel the erosion of metal parts slows down which results in longer life for diesel engines.

Download DFK Catalouge : Click Here

Other Project

Project Gallery